Automotive

- Home

- Case Studies

- Automotive

Automotive

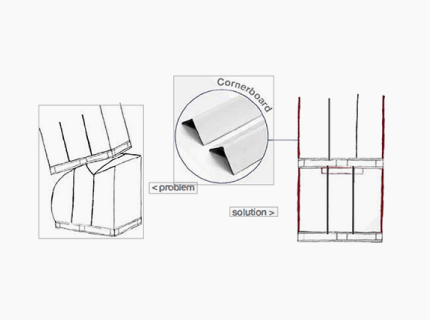

A manufacturer of heavy automotive components had issues with boxes collapsing when double stacking and due to pallets moving the contents were being damaged and some even protruded through the corrugated cases they were packed in.

With up to 800kg in each case this would need special consideration.

During initial assessment the heavy boxes were moved several times at the customers plant prior to despatch and the transport journey was usually a few hundred miles.

Storage also was a concern as it was often cold and damp.

After initial assessment and on site visit to the manufacturing plant and a supermarket delivery we proposed a two fold solution.

Step one was to introduce a 50 x 50 x 3mm edge protection (Angleboard) which would hold the pallet upright.

These conditions combined with the weight involved would make paper products unsuitable. We therefore trialled our composite product (Cornerboard) in a 75 x 75 x 5mm profile.

Transit trials immediately showed an improvement in stability and although the storage conditions were not ideal the composition of the Cornerboard did not deteriorate even after 12 weeks in storage (Average is 6 weeks).

Out of 140 pallets sent out initially between 5-10 were rejected, since the introduction of Cornerboard they have had no rejections whatsoever.